- Home

- High cycle mold(ハイサイクル金型)

High cycle mold(ハイサイクル金型)

What is Diffusion Bonding? Precision jig / parts High cycle mold

About the technology used to shorten the cooling time of the mold

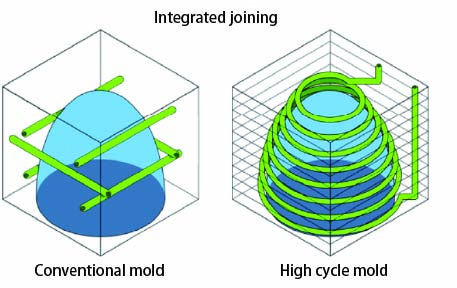

Using diffusion bonding to create a high cycle mold with a built-in cooling water channel for uniform molding.

Since conventional molds can only process linear flow paths, it was not possible to evenly arrange the flow paths on the molding surface.

However, with Yamatech’s diffusion bonding technology, it is possible to forge the mold in slices.

By laminating and bonding each plate, it is possible to design curved flow paths that are evenly distributed on the molding surface.

Molds with internal cooling water channels that could not be made by the conventional mold manufacturing methods, like cutting or casting, can be made using diffusion bonding.

By stacking and joining laminated plates, we are no longer restricted by the manufacturing method and can offer more logical and effective molds.

■ぼたんまだ

The Merits of Yamatech’s High Cycle Mold

Since the cooling water channels can be evenly arranged on the mold’s surface, hot spots are less likely to occur and precise temperature control is possible. Furthermore, the cooling function is very efficient.

By using the diffusion bonding technology, it is possible to forge the mold in slices.

Yamatech’s High Cycle Mold

・Dramatically improves productivity by significantly shortening the cooling time, which accounts for a large proportion of the molding cycle

・Very precise temperature control improves mold’s appearance, accuracy and strength.

・By improving productivity, it is possible to reduce the amount of equipment and molds.

・Maintains the same strength as conventional molds.

■ぼたんまだ

Yamatech’s “High Cycle Mold” supports large sizes up to 1000 mm x 1000 mm.

■ぼたんまだ